FG7OH1M1/FG7OH2M1

Application and Description

These cables are suitable for environments with high fire hazards risk, where it’s essential to guarantee the safety of people and preserve systems and equipments from the corrosive gases (e.g. schools, hospitals, public premises, hotels, supermarkets, tubes, cinemas, theatres, discotheques, public offices). For fixed installation, both indoor and outdoor, on walls and metallic frames.

Standard and Approval

- CEI 20-13, CEI 20-11, CEI 20-22 III, CEI 20-35 (EN60332-1), CEI 20-37 pt.2 (EN50267)

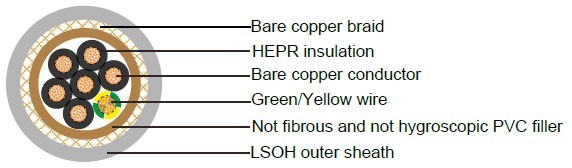

Cable Construction

| Flexible bare copper conductor to CEI 20-29 cl.5 |

| Rubber HEPR, G7 quality,acc. to CEI 20-11 |

| Not fibrous and not hygroscopic filler |

| Bare copper tape screen(for FG7OH1M1) |

| Bare copper wire braid(for FG7OH2M1) |

| Grey LSOH,type M1 outer jacket |

Technical Characteristics

| WORKING VOLTAGE |

600/1000 V |

| TEST VOLTAGE |

4000 V |

| MINIMUM BENDING RADIUS |

8 x O |

| FLEXING TEMPERATURE |

0o C to +90o C |

| STATIC TEMPERATURE |

-25o C to +90o C |

| MAXIMUM SHORT CIRCUIT TEMPERATURE |

+250o C |

| FLAME RETARDANT |

CEI 20-22 III - IEC 60332-3-24 |

| INSULATION RESISTANCE |

10 MΩ x km |

Cable Parameter

| AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA |

NOMINAL THICKNESS OF INSULATION |

NOMINAL THICKNESS OF SHEATH |

NOMINAL OVERALL DIAMETER |

NOMINAL WEIGHT |

| |

# X MM^2 |

MM |

MM |

MM |

KG/KM |

| power |

| 16(30/30) |

2 x 1.5 |

0.7 |

1.8 |

12.6 |

241 |

| 14(50/30) |

2 x 2.5 |

0.7 |

1.8 |

13.5 |

280 |

| 12(56/28) |

2 x 4 |

0.7 |

1.8 |

14.5 |

336 |

| 10(84/28) |

2 x 6 |

0.7 |

1.8 |

15.5 |

395 |

| 8(80/26) |

2 x 10 |

0.7 |

1.8 |

18.4 |

567 |

| 6(128/26) |

2 x 16 |

0.7 |

1.8 |

20.5 |

738 |

| 4(200/26) |

2 x 25 |

0.9 |

1.8 |

25.3 |

1107 |

| 2(280/26) |

2 x 35 |

0.9 |

1.8 |

27.7 |

1403 |

| 1(400/26) |

2 x 50 |

1 |

1.8 |

30.6 |

1830 |

| 2/0(356/24) |

2 x 70 |

1.1 |

1.8 |

36.4 |

2571 |

| 3/0(485/24) |

2 x 95 |

1.1 |

1.8 |

39.0 |

3143 |

| 4/0(614/24) |

2 x 120 |

1.2 |

1.8 |

46.3 |

4316 |

| 250MCM |

2 x 150 |

1.4 |

1.8 |

52.8 |

5547 |

| 16(30/30) |

3 x 1.5 |

0.7 |

1.8 |

13.0 |

262 |

| 14(50/30) |

3 x 2.5 |

0.7 |

1.8 |

14.1 |

316 |

| 12(56/28) |

3 x 4 |

0.7 |

1.8 |

15.0 |

380 |

| 10(84/28) |

3 x 6 |

0.7 |

1.8 |

16.1 |

456 |

| 8(80/26) |

3 x 10 |

0.7 |

1.8 |

19.3 |

675 |

| 6(128/26) |

3 x 16 |

0.7 |

1.8 |

22.3 |

939 |

| 4(200/26) |

3 x 25 |

0.9 |

1.8 |

26.6 |

1346 |

| 2(280/26) |

3 x 35 |

0.9 |

1.8 |

29.2 |

1744 |

| 1(400/26) |

3 x 50 |

1 |

1.8 |

32.3 |

2262 |

| 2/0(356/24) |

3 x 70 |

1.1 |

1.9 |

38.5 |

3188 |

| 3/0(485/24) |

3 x 95 |

1.1 |

2 |

44.2 |

4309 |

| 4/0(614/24) |

3 x 120 |

1.2 |

2.1 |

51.6 |

5635 |

| 250MCM |

3 x 150 |

1.4 |

2.3 |

56.6 |

6921 |

| 350MCM |

3 x 185 |

1.6 |

2.4 |

60.2 |

8079 |

| 450MCM |

3 x 240 |

1.7 |

2.6 |

69.7 |

10639 |

| - |

3 x 35 + 25 |

0.9 |

1.8 |

31.1 |

2038 |

| - |

3 x 50 + 25 |

1 |

1.8 |

34.7 |

2606 |

| - |

3 x 70+ 35 |

1.1 |

1.9 |

39.8 |

3540 |

| - |

3 x 95 + 50 |

1.1 |

2.1 |

45.9 |

4818 |

| - |

3 x 120 + 70 |

1.2 |

2.2 |

53.9 |

6358 |

| - |

3 x 150 + 95 |

1.4 |

2.4 |

59.0 |

7852 |

| - |

3 x 185 + 95 |

1.6 |

2.6 |

62.8 |

9066 |

| - |

3 x 240 + 150 |

1.7 |

2.8 |

73.0 |

12078 |

| 16(30/30) |

4 x 1.5 |

0.7 |

1.8 |

13.8 |

298 |

| 14(50/30) |

4 x 2.5 |

0.7 |

1.8 |

14.9 |

357 |

| 12(56/28) |

4 x 4 |

0.7 |

1.8 |

16.1 |

438 |

| 10(84/28) |

4 x 6 |

0.7 |

1.8 |

17.3 |

535 |

| 8(80/26) |

4 x 10 |

0.7 |

1.8 |

20.8 |

802 |

| 6(128/26) |

4 x 16 |

0.7 |

1.8 |

24.6 |

1164 |

| 4(200/26) |

4 x 25 |

0.9 |

1.8 |

28.8 |

1664 |

| 16(30/30) |

5 x 1.5 |

0.7 |

1.8 |

14.9 |

351 |

| 14(50/30) |

5 x 2.5 |

0.7 |

1.8 |

16.2 |

424 |

| 12(56/28) |

5 x 4 |

0.7 |

1.8 |

17.5 |

527 |

| 10(84/28) |

5 x 6 |

0.7 |

1.8 |

18.9 |

635 |

| 8(80/26) |

5 x 10 |

0.7 |

1.8 |

23.7 |

1027 |

| 6(128/26) |

5 x 16 |

0.7 |

1.8 |

26.9 |

1415 |

| 4(200/26) |

5 x 25 |

0.9 |

1.8 |

31.6 |

2022 |

| control |

| 16(30/30) |

7 x 1.5 |

0.7 |

1.8 |

15.7 |

399 |

| 16(30/30) |

10 x 1.5 |

0.7 |

1.8 |

17.8 |

503 |

| 16(30/30) |

12 x 1.5 |

0.7 |

1.8 |

19.2 |

574 |

| 16(30/30) |

16 x 1.5 |

0.7 |

1.8 |

21.0 |

690 |

| 16(30/30) |

19 x 1.5 |

0.7 |

1.8 |

22.6 |

813 |

| 16(30/30) |

24 x 1.5 |

0.7 |

1.8 |

24.6 |

927 |

| 14(50/30) |

7 x2.5 |

0.7 |

1.8 |

17.1 |

496 |

| 14(50/30) |

10 x 2.5 |

0.7 |

1.8 |

19.5 |

644 |

| 14(50/30) |

12 x 2.5 |

0.7 |

1.8 |

21.2 |

732 |

| 14(50/30) |

16 x 2.5 |

0.7 |

1.8 |

24.0 |

950 |

| 14(50/30) |

19 x 2.5 |

0.7 |

1.8 |

25.0 |

1056 |

| 14(50/30) |

24 x 2.5 |

0.7 |

1.8 |

38.3 |

1281 |